We all have different instincts. For example, I naturally like to fix things, even if they are not broken.

In the past, PLCs were considered the enemy of hard-wired relay panels, companies that made big profits supplying 18-gauge wire and terminal blocks, and panel manufacturers who also kept production lines running by wiring up lots of relays and timers to those panels.

Since the control system is now part of the PLC-controlled process, there is no longer a need to try to find a loose connection or a damaged relay coil to solve automation problems.

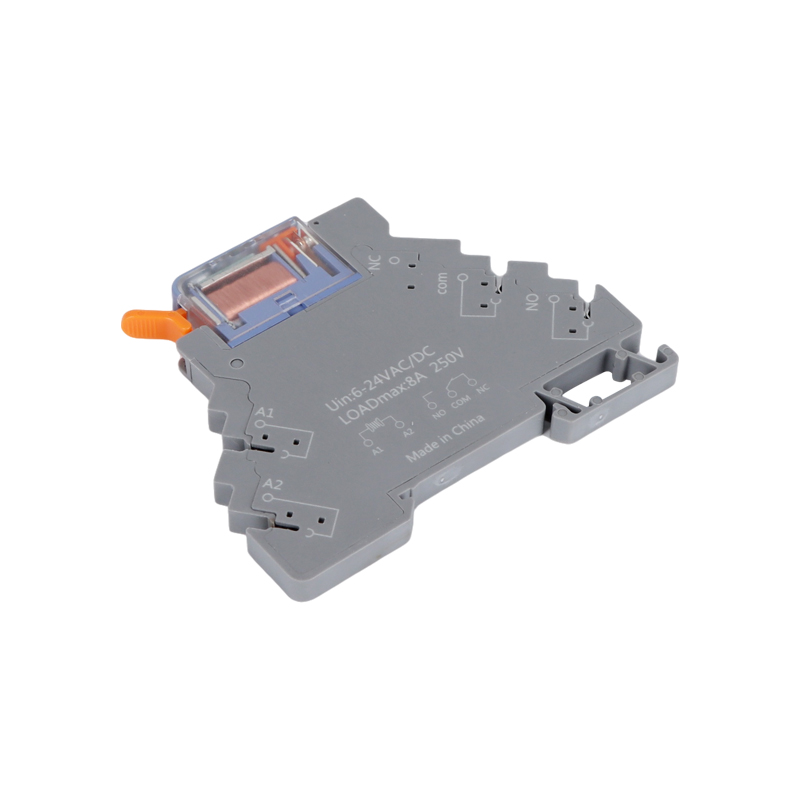

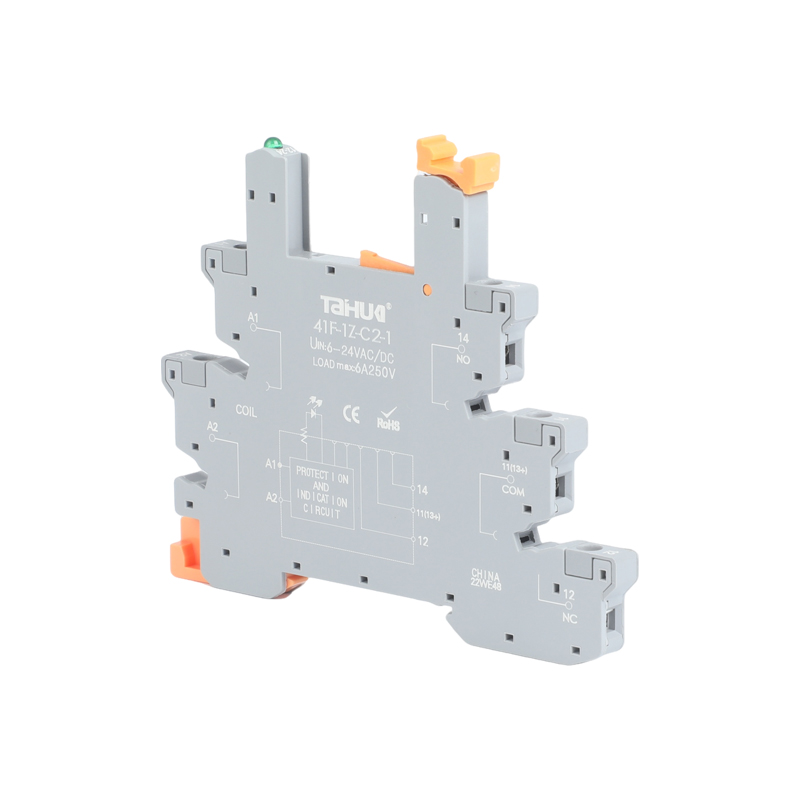

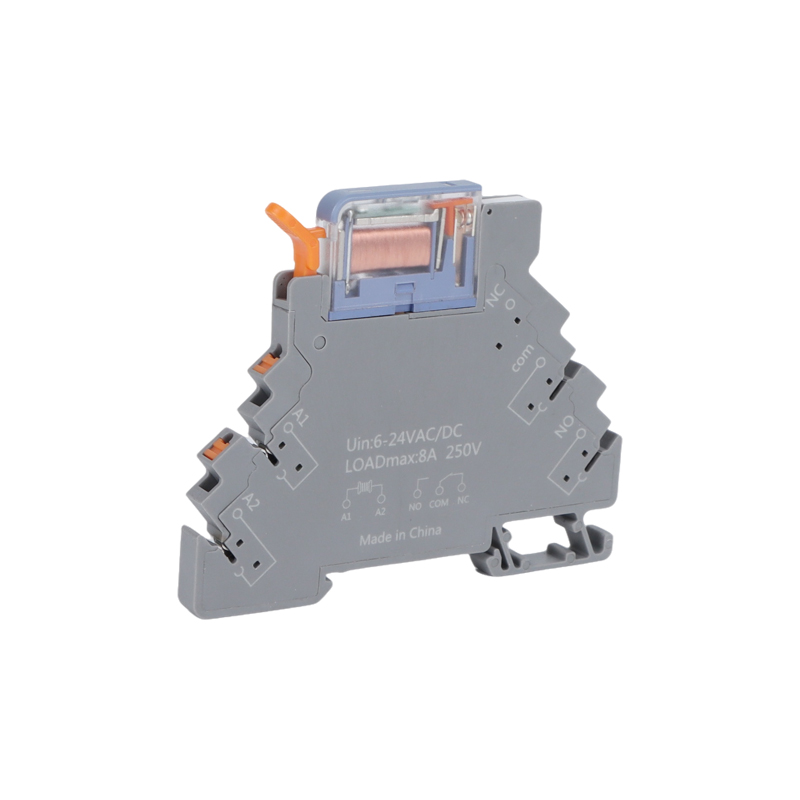

Relay panels are a thing of the past, but hardwired systems and equipment are not. I have seen many PLC panels with safety relays, external timers, and relays to perform functions that are not possible inside the PLC.

I’m sure 16/18 gauge wire is still being produced in record quantities, but its uses have changed dramatically.

In our world of distributed I/O, there are many applications that don’t even use discrete cables. For example, a standard photocell with an IP67 connector. It uses a cable to connect the device to some kind of hub, which is usually connected to a PLC via Ethernet. No cables required. But it’s still hardwired.

The advent of I/O-based wiring protocols and systems has had an impact on the operation of wiring and terminal blocks, but not on the production of the wires themselves. The wire and cable market has been growing steadily since 2016, which is not surprising since it is mainly related to high voltage and housing. However, for automation, the situation has changed.

This is not to say that panel builders are not artists with their cable trays, raceways, and cable ties. The panels from past projects were beautiful—wire runs and bundles neatly hidden, meticulously numbered. Some people take pride in their panel work, but it’s easier to be an artist when there are fewer wires.

Another enemy of the wired is the emergence of wireless devices. They are mainly used in the manufacturing industry and replace the use and installation of wired equipment.

But everything needs electricity, and energy harvesting technology is applied to low-power devices. Industrial Internet of Things (IIoT) devices fall into this category.

Thus, in our automated world, the use of control lines has diminished, but their importance has never diminished.

When I first started working in a training program for an automation supplier, there was a period where I had to spend time assembling equipment on site – I mean motor control center (MCC) terminal blocks, where the equipment was connected to terminal blocks on the terminal block itself. These terminal blocks were for customer use. In this case, there really was no other choice. Typically, the MCC also had a PLC as the control component of the system, so the I/O was hardwired between the MCC terminal block and the PLC part.

Another great experience was hardwiring a discrete digital logic system using 24 gauge wire and a wire wrap tool. Although I joke – it was a real pain – it was my first foray into the world of panel wiring. It taught me the benefits of proper termination, artistry, precision, and of course, wire numbering. I found that there is a knack to following a wiring diagram.

There will always be hard wiring in the panel; it’s just a question of how much wiring is actually used. In my last project, we used a PLC with a frequency converter communicating via Modbus. The panel was used to control a remote wastewater pumping station for a local village.

Although there is some pilot equipment, the main interface is the human-machine interface (HMI), which communicates with the PLC via Ethernet. There are also three level sensors, which have a special interface module external to the PLC. The integrator responsible for the panel design connected the control equipment directly to the PLC without using terminal blocks, which makes the panel very neat. The amount of control wiring is minimal, but it is necessary.

Hardwiring will never go away. It is certainly the easiest way to connect inside the panel, but perhaps not the way to connect outside the panel to the real world. As long as panels exist, long live hardwiring.

Jeremy Pollard, CET, has been writing about technology and software for many years. Pollard has been programming and training control systems for over 25 years.

Jeremy Pollard, CET, has been writing about technology and software for many years. Pollard has been programming and training control systems for over 25 years.

Post time: Jun-11-2025